About us

Baoding Liyuan copper parts manufacturing Co., Ltd. has focused on the copper casting industry for more than 40 years. The company covers an area of 28000 square meters. It is a technical production enterprise that always focuses on the casting and processing of copper and copper alloy.

◆ About us◆ President address◆ Development history◆ Qualifications honors◆ Plant

News

Baoding Liyuan copper parts manufacturing Co., Ltd. has focused on the copper casting industry for more than 40 years. The company covers an area of 28000 square meters. It is a technical production enterprise that always focuses on the casting and processing of copper and copper alloy.

◆ Company news◆ Industry trends◆ Daily copper price

Products

Baoding Liyuan copper parts manufacturing Co., Ltd. has focused on the copper casting industry for more than 40 years. The company covers an area of 28000 square meters. It is a technical production enterprise that always focuses on the casting and processing of copper and copper alloy.

◆ Pure copper casting◆ Brass casting◆ Beryllium copper casting◆ Aluminum bronze casting◆ Tin bronze casting◆ Copper casting for pump valve◆ Copper parts of railway catenary◆ Copper parts of explosion-proof tools

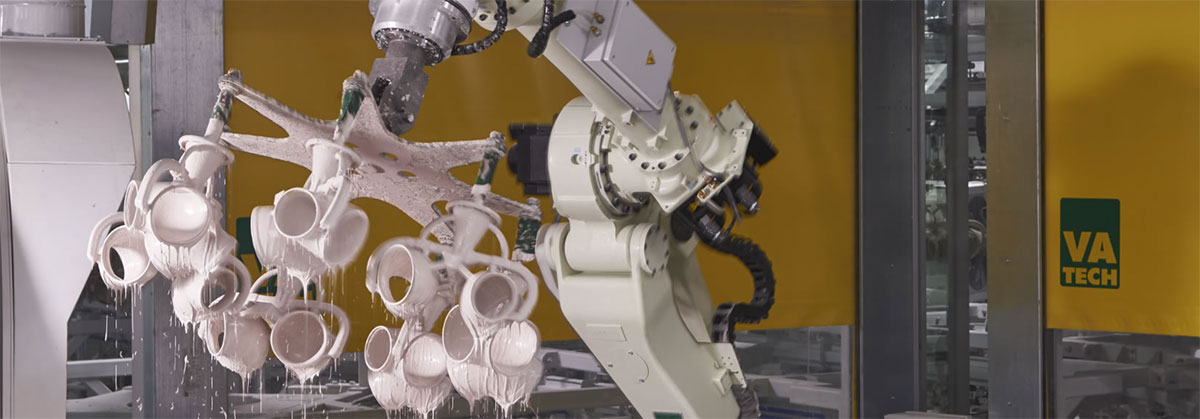

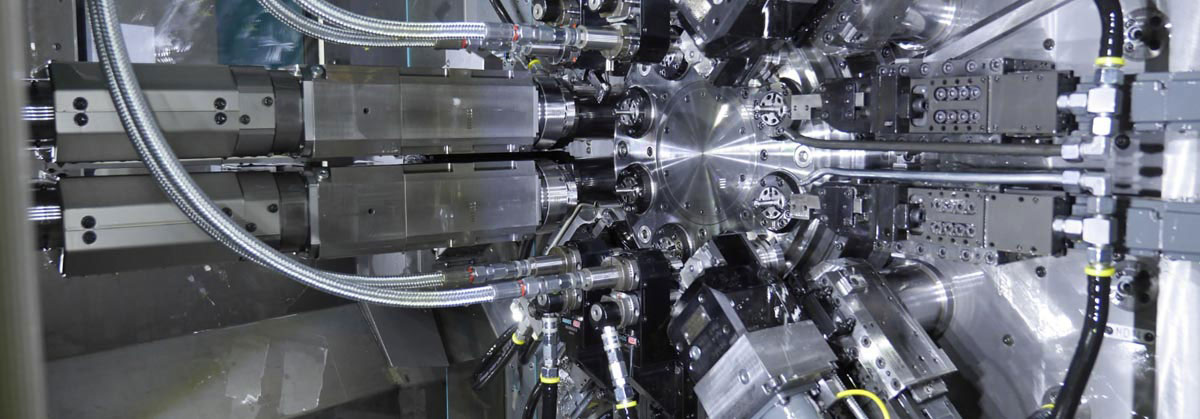

Technology

The company is mainly engaged in the R & D, production and sales of copper alloy castings with high performance, high precision, high conductivity, high strength and high difficulty.

◆ One stop solution◆ Investment casting process◆ Casting technology of coated sand◆ Metal mold casting process◆ Precision machining◆ Quality inspection center

Online enquiry

Baoding Liyuan copper parts manufacturing Co., Ltd. has focused on the copper casting industry for more than 40 years. The company covers an area of 28000 square meters. It is a technical production enterprise that always focuses on the casting and processing of copper and copper alloy.

Contact us

Baoding Liyuan copper parts manufacturing Co., Ltd. has focused on the copper casting industry for more than 40 years. The company covers an area of 28000 square meters. It is a technical production enterprise that always focuses on the casting and processing of copper and copper alloy.

中文

中文 EN

EN